GASMICRO™ ELECTRONIC VOLUME CORRECTOR Galvanic Vietnam, Galvanic Việt Nam đại lý Galvanic Việt Nam, nhà phân phối Galvanic Việt Nam

Xuất sứ: USA

Nhà cung cấp: Pitesco

Hãng sản xuất: Galvanic

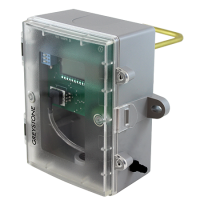

GASMICRO™ ELECTRONIC VOLUME CORRECTOR

Whether you are on the sending or receiving end of the natural gas distribution system, you want to be assured that the actual value of the transported gas is assessed correctly. While that requires a precise measurement of Btu content, it is just as important to determine the actual volume of gas delivered, corrected for temperature and pressure. That’s not possible with a turbine or rotary flow meter alone.

A Three-In-One Measurement Device is the Most Economical Electronic Volume Corrector on the Market Today

Galvanic’s GasMicro instrument is a three-in-one measurement device that calculates the corrected volume, according to AGA7 and AGA8. The GasMicro device is ideal for both remote-mount and instrument-mount applications. In the former, the turbine and rotary meter sends an electronic signal to the GasMicro instrument that represents the volume of gas that the meter has measured, and then the GasMicro calculates the corrected volume. In the latter, Galvanic’s instrument is mounted directly to the turbine or rotary gas meter through a mechanical instrument drive and the GasMicro instrument generates the electrical signal that represents the volume of gas that the meter measured. It then calculates the corrected volume. In both scenarios, the GasMicro device logs and stores the resulting data in memory for record keeping, and ultimately, for data distribution.

FEATURES

- Measurement Canada-approved for custody transfer with 12-year initial re-verification for pressure and temperature

- User-friendly GasMicro IMACS® Windows® PC software with point-&-click/drop-&-drag functionality for easy local or remote configuration

- Fully configurable Modbus (Enron RTU) & three levels of password protection for optimal Specifications (see pdf)

- Automated options include: automated meter reading/reporting & configurable alarms capable of initiating automatic dial-out alarm or email notifications

- AGA 7 & AGA 8 volume-correction calculation methods

- Instrument mount with integrated pulse generator for turbine, rotary, diaphragm or positive-displacement meter with optional remote pulse configuration to receive a pulse from the meter or any other pulse output device

- Pulse outputs for controlling odorant or other process devices

- Reverse flow and rocking-detection compensation

- Long battery life with redundant supplies using alkaline or lithium batteries

- Solar power or external 110VAC – 12VDC switching supply available

- Rugged design with industrial components and four-year comprehensive warranty

- Redundant mechanical backup measurement for continuous measurement – even with electronic failure!

SELECTED INDUSTRIES & APPLICATIONS

- Natural Gas Distribution

- Electronic volume correction

- Pressure measurement

Mr. Tú

Mr. Tú