CS1000-S, CS1000 Proton, Extrusion Controller Proton VietNam Bộ điều khiển đùn PROTON VIET NAM

Hãng sản xuất: PROTON VIETNAM

Features

- Provide PI control of insulation thickness on wire and cable insulation extrusion lines.

- Proton Products advanced line control software runs on the NEXiS® CS5G touch screen industrial PC which controls either a NEXiS® CS1000-S or NEXiS® CS1000-T controller unit.

- Can control either one extruder or capstan drive (NEXiS® CS1000-S) or two extruders (NEXiS®CS1000-T) for double extrusion lines (such as for nylon jacketed, PVC-insulated THWN or THHN cables).

- NEXiS® CS1000-S controller can receive diameter measurement data from up to 3 DG gauges; NEXiS® CS1000-T controller can receive diameter measurement data from up to 6 DG gauges.

- Independent setting of tolerances, shrinkage, alarm functions and speed input.

- Highly versatile and customizable control solution which can be adapted to almost any extrusion application.

- Integrates seamlessly with Proton Products InteliSENS®SL and SLR Series Speed and Length Gauges for line speed measurement.

- Integrates seamlessly with Proton Products InteliSENS®DG series diameter gauges for insulation diameter measurement.

- Housed in a 19-inch rack-mountable enclosure.

Introduction

The Proton Products NEXiS® CS5G Series of controllers are for use on wire insulation or other extrusion production lines.

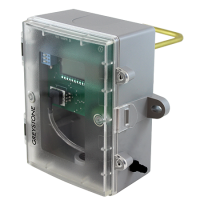

NEXiS® CS5G Systems consist of a NEXiS® CS5G touch screen PC connected to either a NEXiS® CS1000-S (single extruder or capstan drive) or NEXiS® CS1000-T (double extruder) controller. The NEXiS® CS5G functions as a sophisticated user interface for configuring and monitoring the NEXiS® CS1000 controller.

NEXiS® CS1000 controllers connect to Proton Products diameter gauges and speed and length gauges for measurement of insulation diameter and line speed respectively. These measurements are then fed into a PI feedback controller whose fully-isolated and floating output may be used to drive insulation extruders or capstan drives.

Insulation diameter is thus actively controlled and kept within tolerance by the NEXiS® CS1000 controller.

Variants

| Variants | Description |

|---|---|

| NEXiS® CS5G + CS1000-S | Single channel controller supports one PI feedback control output and up to 3 DG gauges. |

| NEXiS® CS5G + CS1000-T | Dual channel controller supports two PI feedback control outputs and up to 6 DG gauges. |

Specifications

NEXiS® CS5G touch screen PC

| Screen | 17-inch colour graphical touch screen display |

NEXiS® CS1000-S controller

(NEXiS® CS1000-T controllers duplicate all functions below for a total of 6× DG Series gauges and 2× PI Controller outputs).

| Serial communications | RS232 | USB | CANbus - (for connection to up to 3× DG Series gauges) | |||

| Line speed inputs | Analogue | Two inputs available for 0 to 10V and 0 to 50V analogue line speed signals; end-user configurable scaling | ||||

| Pulse | Two inputs available for 0 to 3V and 0 to 10V pulsed line speed signals; maximum frequency 250 kHz; end-user configurable scaling | |||||

| 4×Relay contact outputs | Function (end-user configurable) | Gauge OK | SSFD lump or neck flaw detected | X or Y upper tolerance exceeded | X or Y lower tolerance exceeded | |

| X upper tolerance exceeded | X lower tolerance exceeded | Y upper tolerance exceeded | Y lower tolerance exceeded | |||

| Electrical | Maximum voltage | 50VDC / 30VAC | ||||

| Maximum current | 500mA | |||||

| On resistance (@ 100mA) | < 0.1Ω | |||||

| Off resistance | > 10 MΩ | |||||

| Analogue output 1 | Function (end-user configurable) | ØX | ØXY | |||

| Electrical | Output voltage range | 0V to +10V | ||||

| Maximum output current | 2mA | |||||

| Resolution | 16-bit | |||||

| Output voltage scaling is end-user configurable | ||||||

| Analogue output 2 | Function (end-user configurable) | ØY | Average Error | |||

| Electrical | Output voltage range | ØY: 0V to +10V | ||||

| Average Error: -10V to +10V | ||||||

| Maximum output current | 2mA | |||||

| Resolution | 16-bit | |||||

| Output voltage scaling is end-user configurable | ||||||

| Control algorithm | Advanced Control Algorithm (ACA) | |||||

| SPC | Graphical histogram | Cp | Cpk | |||

| SPC control | Statistical Process Control: minimize insulation material consumption whilst maintaining in tolerance insulation diameter | |||||

| FFT | Fast Fourier Transform: displays amplitude versus frequency of periodic diameter variations | |||||

| SSFD | Single Scan Flaw Detection: detection of lump and neck flaws | |||||

| Presets | Nominal diameter | +Tolerance | -Tolerance | +Flaw (Lump) | -Flaw (Neck) | |

| Product recipes | 50 sets of product presets may be stored in memory for rapid recall | |||||

| Statistics | Mean diameter | Standard deviation (sigma) | Maximum diameter | Minimum diameter | ||

| Specification | Minimum | Typical | Maximum | Units |

|---|---|---|---|---|

| Power supply voltage (rms) | 84 | 264 | VAC | |

| Power supply frequency | 47 | 440 | Hz | |

| Power supply current (rms) | 1 | A | ||

| Power consumption | 35 | W | ||

| Ambient temperature | 5 | 45 | °C | |

| 41 | 113 | °F | ||

| Relative humidity @ 38°C / 105°F | 90 | % | ||

| Ingress Protection (IP) rating | IP50 | - | ||

| PI Controller output voltage | -10 | 10 | V | |

| PI Controller output current | 10 | mA | ||

| PI Controller output resistance | 10 | Ω | ||

| PI Controller resolution | 12 | bit |

Mr. Tú

Mr. Tú