Avtron XR12 SMARTSafe™ Sensor Nidec-Avtron VIET NAM

Hãng sản xuất: Nidec-Avtron

http://www.nidec-avtron.com/encoders/family/heavy-mill-duty/xr12

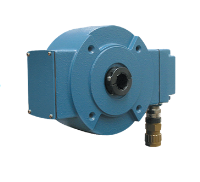

Large Bore Hazardous Duty Encoder Sensor

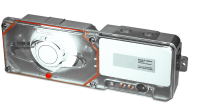

- • cULus Class I, Div 1 Listed, Groups A,B,C,D

- • cULus Class I Zone Group IIC

- • cULus Class I, Div 2 Listed, Groups A,B,C,D

- • ATEX IECEx Rated: Zone 1 & 2, 21 & 22

- • Fits Shafts up to 7 7/8" [200mm]

- • Ideal for Oil and Gas Drilling

- • Fully Potted Electronics

- • Up to 8192 PPR

- • Wide Sensor-Rotor Gap: No Shimming or Scraping

- • 3 Year No-Hassle Warranty

XR12 SMARTSafe™ modular incremental quadrature encoder sensors enable the world's first hazardous duty rotary encoders with removable electronics. They are cULus, ATEX and IECEx certified and offer incredibly reliable no-bearing construction! SMARTSafe sensors can be used in ATEX/IECEx gas and dust and UL gas hazardous environments. Also available: hollow shaft models (XR685), shafted models (XR485), no-bearing modular encoders (XR125, XR850), and modular sensors for smaller bore applications (XR5).

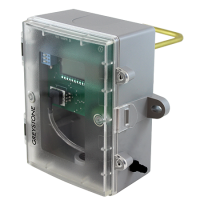

For Level 2 applications requiring ATEX/IECEx Zone 2 or 22 or cULus Class I, Division 2, Groups A,B,C,D use the XR12 directly in your application, with no barrier, isolator or cable gland required.

For Level 1 applications requiring ATEX/IECEx Zone 1 or 21 protection use the XRB1 or XRB2 isolator in your control cabinet which permits the use of intrinsically safe wiring instead of explosion-proof conduit or glands. The XR56 can also be used in UL Class I Div 1 & Zone 0 applications using the XRB2 Isolator.

Unlike the competition, Avtron SMARTSafe encoder systems are protected against short circuits, power-to-output wiring, and output-to-ground faults.

Instead of mounting a tiny optical encoder with weak bearings on a wobbling stub shaft, mount XR12 directly on your machine and install the rotor on your main application or motor shaft. Vibration, shock, liquids, dust and dirt won't harm SMARTSafe™ XR12 encoders! Paint booths, draw works, coil tubing rigs...XR12 can keep them all working 24-7-365.

Eliminate the biggest cause of industrial encoder failure--eliminate the bearings with XR12 hazardous duty encoder sensors.

For Level 2 applications requiring ATEX/IECEx Zone 2 or 22 or cULus Class I, Division 2, Groups A,B,C,D use the XR12 directly in your application, with no barrier, isolator or cable gland required.

For Level 1 applications requiring ATEX/IECEx Zone 1 or 21 protection use the XRB1 or XRB2 isolator in your control cabinet which permits the use of intrinsically safe wiring instead of explosion-proof conduit or glands. The XR56 can also be used in UL Class I Div 1 & Zone 0 applications using the XRB2 Isolator.

Unlike the competition, Avtron SMARTSafe encoder systems are protected against short circuits, power-to-output wiring, and output-to-ground faults.

Instead of mounting a tiny optical encoder with weak bearings on a wobbling stub shaft, mount XR12 directly on your machine and install the rotor on your main application or motor shaft. Vibration, shock, liquids, dust and dirt won't harm SMARTSafe™ XR12 encoders! Paint booths, draw works, coil tubing rigs...XR12 can keep them all working 24-7-365.

Eliminate the biggest cause of industrial encoder failure--eliminate the bearings with XR12 hazardous duty encoder sensors.

Mr. Tú

Mr. Tú