VISCOSITE™ IN-LINE VISCOMETERS

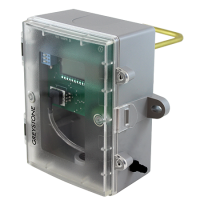

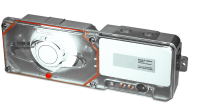

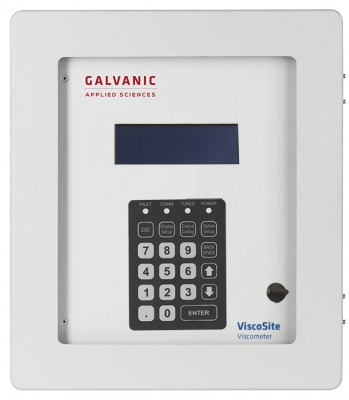

Whether you are blending asphalts or foods, refining oil or petrochemicals, or manufacturing consumer products, pharmaceuticals, or industrial polymers – precise, real-time viscosity measurements are critical to assuring product consistency and quality. Galvanic’s ViscoSite viscometers are dual component systems consisting of the transmitter and the sensor. The sensor is hermetically sealed from the process and welded to a base that is installed in the reactor, tank, or pipe. This ensures that the desired product quality will be achieved because the sensor can be installed at the point in the process where the critical viscosity measurement must occur. The application specific sensors are suitable for many applications including:

• Batch polymer processing

• Continuous polymer processing

• Asphalt blending

• Fuel blending

• Food processing

• Paper coating manufacturing

• Liquid detergent blending

FEATURES

- Reliable measurement in harsh flow conditions – varying flow rate, suspended solids, high temperature, and high pressure

- Flow variations, produced by a reactor agitator or pipeline flow, have no influence on the ViscoSite measurement

- An RTD (PT100) is integrated into the sensors to provide temperature measurement at the same location as the viscosity measurement

- Safety barriers (i.e., Zener) are used to make ViscoLiner sensors suitable for installation in hazardous areas

- Factory-calibrated to NIST-traceable standards and no moving parts − because there is no wear and tear from the instrument itself, recalibration is not necessary

Mr. Tú

Mr. Tú