Model 4420-1X-12.5 Titanium Crackmeter (VW) Geokon Vietnam

Hãng sản xuất: Geokon

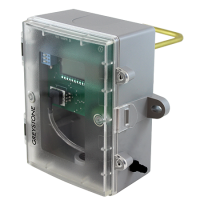

A submerged concrete caisson, partially buried below seabed serving as a water intake facility, was to be instrumented to monitor potential settlements during its operation. To meet the objectives of the monitoring project, two Model 6160 MEMS Tiltmeters (located inside the caisson) were used to monitor any tilting and four Model 4420 Displacement Transducers (12.5 mm range) were installed on each pipe connection to measure longitudinal displacements; 2 on the stainless steel pipe and 2 at the stainless steel to concrete caisson pipe connection. The MEMS tilt sensors were housed inside a protective enclosure which also contained an integral battery powered Model 8002 LC-3 Datalogger for continuous monitoring. The whole assembly was mounted to the caisson using a custom-made titanium mounting bracket. The displacement transducers were also monitored by Model 8002 LC-2 Dataloggers, but were connected via an umbilical cable to permit undersea mounting. The Datalogger enclosures were fully waterproof and constructed from heavy gauge PVC and titanium. The displacement transducers were standard types, installed inside a titanium housing designed to survive the subsea environment. The displacement transducer assembly employed a spring-loaded mechanism to allow ease of mounting, by divers, onto titanium studs installed on either side of the pipe connections. The dataloggers will be retrieved by divers to permit data removal, and then re-installed, onto the same mounts, for continued monitoring.

Mr. Tú

Mr. Tú