DG2030-5k, DG2030-12.5k,DG3030-5k,DG3030-12.5k,Proton Vietnam,Máy đo đường kính PROTON Việt Nam

Hãng sản xuất: PROTON VIETNAM

Features

- Completely solid-state design with no moving parts for very high measurement speed and long term reliability.

- Eye-safe LED illumination.

- Integrated air wipes.

- Comprehensive selection of standard and optional industrial communications interfaces.

- Optional integrated PI feedback controller for controlling extruders or capstan drives on insulation lines.

- Optional integrated lump and neck flaw detection capability (SMFD – Single Measurement Flaw Detection).

- Optional integrated fast Fourier transform (FFT), statistical analysis and Statistical Process Control (SPC) functions available.

DIAMETER MEASUREMENT

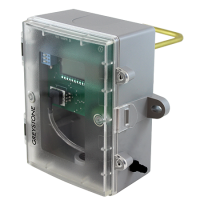

InteliSENS® DG-k Series Diameter Gauge

Features

- Completely solid-state design with no moving parts for very high measurement speed and long term reliability.

- Eye-safe LED illumination.

- Integrated air wipes.

- Comprehensive selection of standard and optional industrial communications interfaces.

- Optional integrated PI feedback controller for controlling extruders or capstan drives on insulation lines.

- Optional integrated lump and neck flaw detection capability (SMFD – Single Measurement Flaw Detection).

- Optional integrated fast Fourier transform (FFT), statistical analysis and Statistical Process Control (SPC) functions available.

Introduction

Proton Products InteliSENS® DG-k series dual and triple-axis diameter gauges are super fast, with scan rates of 1000 to 12500 scans/second/axis, providing outstanding product quality supervision.

Using LED light sources, high-speed Digital Signal Processing (DSP) and specialized optical design to measure, control, inspect, alarm and report diameter as well as Surface Quality Defects (SQD) as they happen, reducing customer complaints and improving your reputation as a quality product supplier.

The LED light sources cover the complete circumference of the product and any change in the diameter is immediately detected by the CCD optical receiver, measuring, controlling, alarming and reporting the diameter as well as the height, length and location of lumps and necks (if the SMFD option is purchased) along and around the product.

Extremely easy to install, integrate and use, InteliSENS® DG-k Series super fast diameter gauges can be used as a stand-alone device or integrated with production line PLCs. Optional audio/visual alarm units, fault printers and data logging PC software are available to complement the diameter gauge and close the loop on quality control.

Applications include production processes such as insulation extrusion and jacketing, wire drawing, quality control during rewinding and coiling, and rubber and plastic extrusion processes for hose, tube and pipe production.

Operating principle

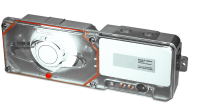

The Proton Products InteliSENS® DG-k series of diameter gauges illuminate each axis of the measured object with light from a LED light source. The measured object obstructs part of the light which is then imaged onto a CCD detector array. Analysis of the pixel data from the CCD yields the object diameter. As this system is entirely solid state, it provides a very fast measurement rate together with the reliability and robustness of a system free from moving parts.

The high measurement rate of the InteliSENS® DG-k series also enables it to function as a lump and neck flaw detector at medium line speeds (< 500 m/min) when purchased with the high speed (12.5k) and SMFD (Single Measurement Flaw Detection) options.

DIAMETER MEASUREMENT

InteliSENS® DG-k Series Diameter Gauge

Features

- Completely solid-state design with no moving parts for very high measurement speed and long term reliability.

- Eye-safe LED illumination.

- Integrated air wipes.

- Comprehensive selection of standard and optional industrial communications interfaces.

- Optional integrated PI feedback controller for controlling extruders or capstan drives on insulation lines.

- Optional integrated lump and neck flaw detection capability (SMFD – Single Measurement Flaw Detection).

- Optional integrated fast Fourier transform (FFT), statistical analysis and Statistical Process Control (SPC) functions available.

Proton Products InteliSENS® DG-k series dual and triple-axis diameter gauges are super fast, with scan rates of 1000 to 12500 scans/second/axis, providing outstanding product quality supervision.

Using LED light sources, high-speed Digital Signal Processing (DSP) and specialized optical design to measure, control, inspect, alarm and report diameter as well as Surface Quality Defects (SQD) as they happen, reducing customer complaints and improving your reputation as a quality product supplier.

The LED light sources cover the complete circumference of the product and any change in the diameter is immediately detected by the CCD optical receiver, measuring, controlling, alarming and reporting the diameter as well as the height, length and location of lumps and necks (if the SMFD option is purchased) along and around the product.

Extremely easy to install, integrate and use, InteliSENS® DG-k Series super fast diameter gauges can be used as a stand-alone device or integrated with production line PLCs. Optional audio/visual alarm units, fault printers and data logging PC software are available to complement the diameter gauge and close the loop on quality control.

Applications include production processes such as insulation extrusion and jacketing, wire drawing, quality control during rewinding and coiling, and rubber and plastic extrusion processes for hose, tube and pipe production.

Operating principle

The Proton Products InteliSENS® DG-k series of diameter gauges illuminate each axis of the measured object with light from a LED light source. The measured object obstructs part of the light which is then imaged onto a CCD detector array. Analysis of the pixel data from the CCD yields the object diameter. As this system is entirely solid state, it provides a very fast measurement rate together with the reliability and robustness of a system free from moving parts.

The high measurement rate of the InteliSENS® DG-k series also enables it to function as a lump and neck flaw detector at medium line speeds (< 500 m/min) when purchased with the high speed (12.5k) and SMFD (Single Measurement Flaw Detection) options.

Specifications

InteliSENS® DG2015-k 15mm Diameter Gauges

|

Model

|

DG2015-5k

|

DG2015-12.5k

|

Units

|

|---|---|---|---|

| Number of axes | 2 | 2 | - |

| Scan rate | 5000 | 12500 | scan/s/axis |

| Cumulative scan rate | 10000 | 25000 | scan/s |

| Update time | 200 | 80 | µs |

| Maximum weight | 3.4 | kg | |

|

Specification

|

Minimum

|

Typical

|

Maximum

|

Units

|

|---|---|---|---|---|

| Object diameter | 0.2 | 15 | mm | |

| Optical gate diameter | 16 | mm | ||

| Accuracy* | -1 | 1 | µm | |

| Output resolution | 1 | µm |

InteliSENS® DG2030-k and DG3030-k 30mm Diameter Gauges

|

Model

|

DG2030-5k

|

DG2030-12.5k

|

DG3030-5k

|

DG3030-12.5k

|

Units

|

|---|---|---|---|---|---|

| Number of axes | 2 | 2 | 3 | 3 | - |

| Scan rate | 5000 | 10000 | 5000 | 10000 | scan/s/axis |

| Cumulative scan rate | 10000 | 25000 | 15000 | 37500 | scan/s |

| Update time | 200 | 80 | 200 | 80 | µs |

| Maximum weight | 5 | 6.5 | kg | ||

|

Specification

|

Minimum

|

Typical

|

Maximum

|

Units

|

|---|---|---|---|---|

| Object diameter | 0.2 | 30 | mm | |

| Optical gate diameter | 32 | mm | ||

| Accuracy* | -1 | 1 | µm | |

| Output resolution | 1 | µm |

* For a < 15mm diameter object centred in the optical gate. Accuracy is ±3μm for a 15 to 30mm diameter object centred in the optical gate. Add an additional 0.05% for objects not centred in the optical gate.

InteliSENS® DG2060-k and DG3060-k 60mm Diameter Gauges

|

Model

|

DG2060-5k

|

DG2060-12.5k

|

DG3060-5k

|

DG3060-12.5k

|

Units

|

|---|---|---|---|---|---|

| Number of axes | 2 | 2 | 3 | 3 | - |

| Scan rate | 5000 | 12500 | 5000 | 12500 | scan/s/axis |

| Cumulative scan rate | 10000 | 25000 | 15000 | 37500 | scan/s |

| Update time | 200 | 80 | 200 | 80 | µs |

| Maximum weight | TBA | 18 | kg | ||

|

Specification

|

Minimum

|

Typical

|

Maximum

|

Units

|

|---|---|---|---|---|

| Object diameter | 0.3 | 60 | mm | |

| Optical gate width | 64 | mm | ||

| Accuracy | ±(3µm + 0.01% of object diameter) | - | ||

| Output resolution | 1 | µm |

InteliSENS® DG2200-k 200mm Diameter Gauge

|

Model

|

DG2200-1k

|

DG2200-3k

|

Units

|

|---|---|---|---|

| Number of axes | 2 | 2 | - |

| Scan rate | 1000 | 3000 | scan/s/axis |

| Cumulative scan rate | 2000 | 6000 | scan/s |

| Update time | 1000 | 333 | µs |

| Maximum weight | TBA | kg | |

|

Specification

|

Minimum

|

Typical

|

Maximum

|

Units

|

|---|---|---|---|---|

| Object diameter | 2 | 180 | mm | |

| Optical gate diameter | 200 | mm | ||

| Accuracy* | ±(10µm + 0.005% of object diameter) | µm | ||

| Output resolution | 0.01 | µm |

* For an object centred in the optical gate.

|

Specification

|

Min

|

Typical

|

Max

|

Units

|

|---|---|---|---|---|

| Operating temperature | 5 | 45 | °C | |

| Environmental protection | IP65 | |||

| For DC power supply models only: | ||||

| DC Power supply voltage | 15 | 24 | 28 | VDC |

| DC Power consumption (with optional AiG2 interface display unit) | 30 | W | ||

| For AC power supply models only: | ||||

| AC Power supply voltage | 85 | 274 | VAC | |

| AC Power supply frequency | 47 | 63 | Hz | |

| AC Power consumption (with optional AiG2 interface display unit) | 40 | W | ||

| Light source | LED | |

| Air wipe | Integrated air wipe system | |

| Measurement units (user configurable) | millimetres (line speed: millimetres / minute, length: metres) | |

| inches (line speed: feet / minute, length: feet) | ||

| Measurement modes | Solid | Solid object diameter |

| Glass | Transparent object diameter | |

Standard Interfaces

| 2x digital inputs | User configurable function | Reset | Print Activation | |||

| Maximum input voltage | 24 Vdc | |||||

| 4x relay outputs | User configurable function | Gauge OK | Upper tolerances exceeded | Lower tolerances exceeded | Single Measurement Flaw Detection (SMFD) | |

| Isolated contact rating | maximum 50 VDC / 30 VAC / 0.5 A | |||||

| Line speed inputs* | Analogue input | 0 - 10 Vdc, user scalable | ||||

| Speed pulse input | 250 kHz max frequency, 30 V or 50 V max pulses (on two distinct inputs), user scalable | |||||

| Communication interfaces | RS-232** | RS-422 | RS-485 | CAN-bus*** | Ethernet | |

*Required for optional PI feedback controller operation

**An optional RS-232-to-USB converter cable is available for connection to USB equipped computers.

**CAN-bus protocol is proprietary and reserved for connection to other Proton Products equipment such as an AiG2 interface display unit.

Optional Interfaces

Must be specified for installation at time of manufacture, cannot be retrofitted.

| 3x Analogue outputs | ±10 Vdc output of diameters or errors, user scalable |

| Wireless communication interfaces | Choice of any one of: Bluetooth* or WiFi* |

| Industrial communication interfaces | Choice of any one of: PROFIBUS, EtherNet/IP or DeviceNET |

*Wireless interfaces are not available in units destined for European markets.

Optional functionality

Must be specified for installation at time of manufacture, cannot be retrofitted.

| PI feedback controller | Proportional Integral feedback controller |

| Statistics | Maximum, minimum, mean, standard deviation, Cp, Cpk |

| SPC | Statistical Process Control automatic set point for PI feedback controller (requires PI feedback controller option) |

| FFT | Fast Fourier Transform analysis for amplitude and frequency of periodic diameter variations |

| SMFD | Single Measurement Flaw Detection (Lump and Neck detection) |

Mr. Tú

Mr. Tú